Common rock/stone crushers are: jaw crusher, impact crusher, cone crusher, roll crusher, hammer crusher and so on.

Different hardness of rocks need to use different crusher, applicable as follows:

Jaw Crusher: ≤320-350 MPa, e.g.: granite, limestone, cobblestone, river stone, construction waste, etc. .

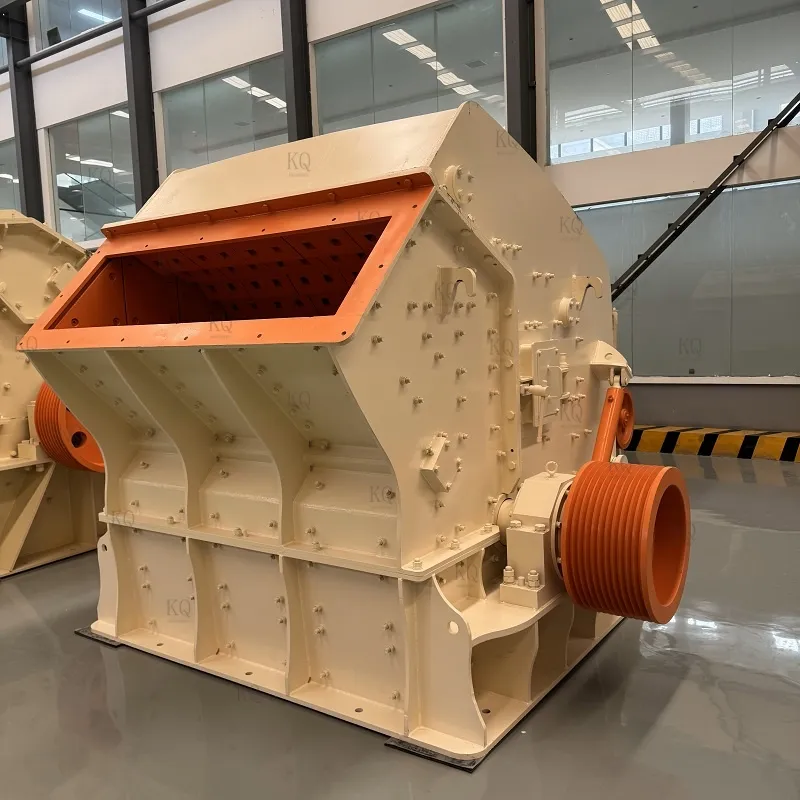

Impact crusher: ≤350 MPa, e.g. limestone, dolomite, gypsum, basalt, pyrophyllite and other medium hardness ores.

Cone crusher: very suitable for crushing medium-hard to hard rocks, such as granite, basalt, quartzite, marble and so on.

Roll Crusher: ≤200MPa, suitable for brittle materials with medium hardness, such as limestone, construction waste, coal, slag, refractory materials and so on.

Hammer crusher: ≤100-200 MPa, suitable for medium hardness, brittle and weak abrasive materials, such as: limestone, coal, salt, gypsum, chalk, brickwork, gangue, etc.

For different sizes and hardnesses of aggregates, according to the actual situation of the customer's site, our engineers can provide different crushing programs according to the customer's requirements, and we can also send engineers to the site for installation and maintenance.

|  |

Jaw crusher: with the advantages of high crushing ratio, even particle size, simple structure, reliable operation, easy maintenance, low operating cost, flexible adjustment of discharge opening, etc., it is suitable for primary crushing of various hardness materials. By optimizing the design of deep cavity, structure and intelligent lubrication and other technologies, our company achieves higher output, stronger bearing capacity, better energy saving and environmental protection (such as low noise, less dust, energy saving of 15-35%). -35%).

Impact crusher: simple structure, strong wear resistance (internal rotor, liner plate and other wear-resistant parts, the use of wear-resistant, corrosion-resistant materials, in the production does not require much maintenance, saving time and labor, the use of adjustable impact plate and plate hammer and over-iron device, greatly reducing equipment wear). The finished products have the advantages of even particle size, good gradation, strong applicability (can be coarse crushing, medium crushing, fine crushing, especially suitable for dealing with high water content materials), long service life of wearing parts, energy saving and environmental protection.

Cone crusher: high efficient crushing, excellent particle size, high degree of automation, can realize crushing instead of grinding, greatly reduce energy consumption and operating costs, especially the hydraulic cone crusher with overload protection, automatic discharge, easy maintenance, etc., through the principle of laminar crushing to achieve the crushing of hard materials, and adaptable, can be replaced by changing the cavity to meet the needs of different particle size.

Roll crusher: simple and compact structure, easy operation and maintenance, smooth operation, low cost, uniform size, low water content requirements for materials, and environmental protection (low noise, low dust); through the adjustment of the roll gap can easily control the size of the discharged material, with the protection of the automatic avoidance of over-hard objects, the finished product is good, suitable for fine and medium crushing operations.

|  |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

The main parts include fixed jaw plate, movable jaw plate, eccentric shaft, connecting rod and adjusting device. The fixed jaw plate is fixed, and the movable jaw plate is driven by the eccentric shaft and connecting rod to do reciprocating motion. The material enters the crushing chamber from the top and is located between the two jaw plates.

The motor drives the eccentric shaft and drives the movable jaw plate to reciprocate, and when it is close to the fixed jaw plate, it squeezes the material to make it crushed. The crushed material is discharged from the bottom by gravity. The distance between the movable jaw plate and the fixed jaw plate can be changed through the adjusting device to control the granularity of the discharged material.

Model | Feeding Size(mm) | Discharge Gatesize (mm) | Capacity(t/h) | Motor Power(kw) | Overall Dimension(mm) |

PE400×600 | ≤350 | 40-90 | 15-60 | 30 | 1650×1588×1050 |

PE500×750 | ≤425 | 50-100 | 40-110 | 45 | 1956×1918×1920 |

PE600×900 | ≤500 | 60-125 | 90-180 | 55 | 2250×2733×2280 |

PE800×900 | ≤600 | 80-140 | 100-220 | 75 | 2450×2950×2490 |

PE750×1060 | ≤630 | 60-150 | 110-380 | 110 | 2531×2455×2783 |

PE900×1060 | ≤700 | 100-160 | 230-390 | 110 | 2900×2657×2950 |

PE900×1200 | ≤750 | 110-165 | 220-450 | 132 | 3100×2760×3260 |

PE1000X1200 | ≤900 | 110-185 | 315-500 | 132 | 3200×2760×3260 |

PE1200×1500 | ≤950 | 115-195 | 550-1000 | 220 | 3710×3446×4075 |