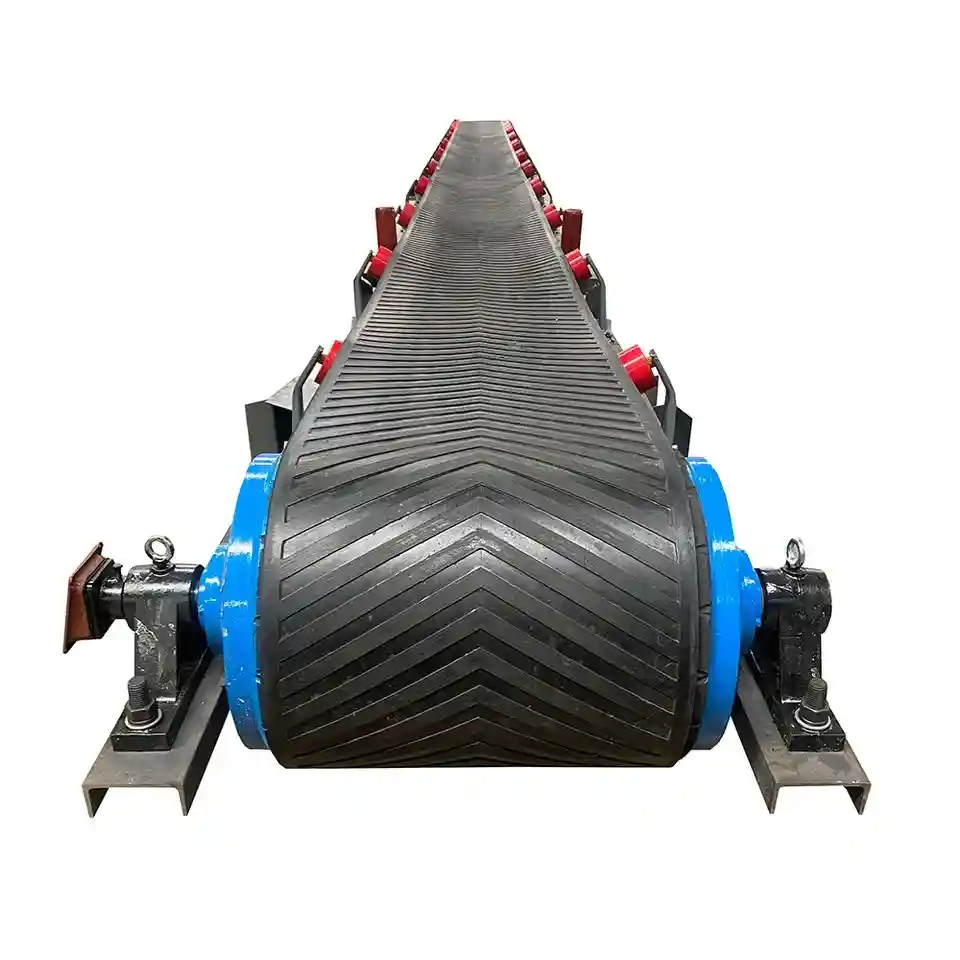

Conveyors play a vital role in industrial operations such as mining, aggregate processing, construction, and chemical manufacturing. Specifically designed for transporting aggregates like sand, gravel, ore, and cement, they utilize a continuous loop belt to carry materials. This enables the bulk, long-distance, and multi-point transfer of materials in both horizontal and inclined directions. They are widely used in applications such as quarries, construction waste processing, and recycling at mixing plants.

|

|

1.Flexible Adaptability:

Available in mobile and stationary configurations, with customizable length, inclination angle, belt width, and belt speed to meet diverse conveying requirements across varying conditions (site layout, output capacity, material properties).

2.High Efficiency & Energy Savings:

Delivers robust and stable continuous conveying capacity. Compared to dump trucks, conveyors offer a more environmentally friendly and economical alternative.

3.Stable and Reliable:

Features a robust, durable structure with key components (e.g., drums, rollers) constructed from high-quality materials. Ensures smooth operation, low failure rates, and uninterrupted production continuity.

4.Eco-Friendly and Clean:

Closed or semi-closed designs (optional) effectively minimize dust dispersion and aggregate spillage. Improves working conditions, reduces material loss, and meets environmental standards.

5.Low-Maintenance and Cost-Effective:

Modular design facilitates easy inspection and replacement of major components, significantly reducing maintenance complexity and downtime.

|

|

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

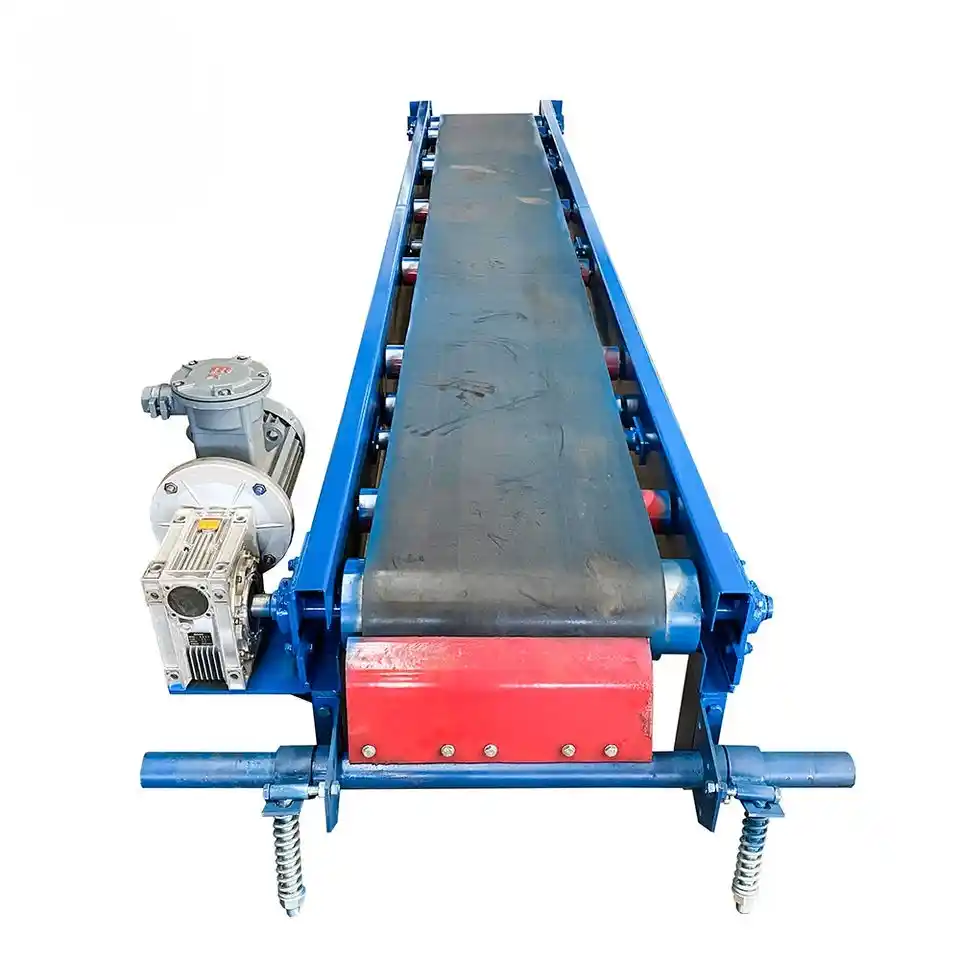

1. Drive: The motor (often paired with a reducer) drives the head drive roller to rotate.

2. Transmission: The drive roller moves the belt conveyor through friction.

3. Loading: Material is uniformly fed onto the conveyor belt's loading section via a hopper (e.g., chute).

4. Conveying: The running belt transports material from the starting point (tail end) to the destination (head end).

5. Support and Guidance: Along the conveying path, upper idlers support the material and belt on the loading section, while lower idlers support the belt on the empty section. Redirecting drums (e.g., tail drum, vertical tensioning drum) ensure belt directional control and tensioning.

6. Unloading: At the head drum, material disengages from the belt via inertia or unloading devices (e.g., discharge chute), completing the conveying process.

Belt Width (MM) | Conveyor length (M) | Belt Speed | Capacity | ||

500 | ≤ 10 / 3 | ≤ 10-25 / 4-7.5 | ≤ 25-45 / 11-18.5 | 1.3-1.6 | 40-100 |

650 | ≤ 10 / 4 | ≤ 10-25 / 5.5-11 | ≤ 25-45 / 15-22 | 1.3-1.6 | 80-120 |

800 | ≤ 10 / 5.5 | ≤ 10-25 / 7.5-15 | ≤ 25-45 / 18.5-30 | 1.3-1.6 | 120-200 |

1000 | ≤ 10 / 5.7 | ≤ 10-25 /11-18.5 | ≤ 25-45 / 22-37 | 1.3-2.0 | 200-320 |

1200 | ≤ 10 / 11 | ≤ 10-25 / 15-22 | ≤ 25-45 / 30-45 | 1.3-2.0 | 300-500 |

1400 | ≤ 10 / 15 | ≤ 10-25 / 18.5-30 | ≤ 25-45 / 37-55 | 1.3-2.0 | >500 |