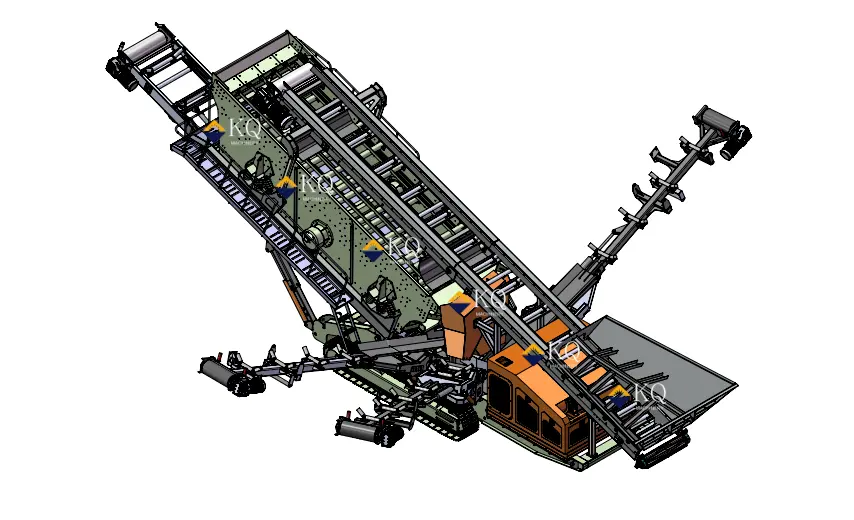

The tracked mobile vibrating screen serves as a critical grading equipment for operations such as mineral screening, construction waste recycling, and tailings processing. Featuring an innovative design that integrates an all-terrain mobile chassis, it combines feeding, screening, and conveying systems into one unit. Capable of autonomous movement to job sites without requiring fixed foundations, it adapts to complex and rugged terrain, enabling on-site material screening and grading. This truly achieves “ready to operate upon arrival.”

|

|

🟠1. Ultimate Flexibility, Rapid Deployment:

Track-driven with hydraulic mobility, 360° on-the-spot turning, and strong climbing capability (up to 30°), effortlessly handles rugged terrain. Ready for operation within 15-30 minutes of site arrival, significantly shortening project timelines.

🟠2. Integrated Efficiency, Precise Screening:

Core equipped with high-performance vibrating screen box (single-layer or multi-layer optional). Adjustable screen inclination and amplitude adapt to diverse materials (sand, gravel, aggregates, construction waste, etc.) and particle size requirements, delivering high screening efficiency and precision.

🟠3. Precise Screening, Integrated Operation:

Achieving over 95% screening accuracy, it can be linked with crushing equipment to form a production line, enhancing overall operational efficiency.

🟠4. Intelligent Operation, Effortless And Worry-Free:

PLC smart control system with integrated touchscreen enables one-touch start/stop, parameter setting, and fault diagnosis. Optional remote control ensures convenient and safe operation.

🟠5. Zero Disassembly For Relocation, Lower Costs:

Integrated design eliminates transport disassembly, saving significant time and hoisting expenses while reducing overall operational costs.

🟠6. Rugged Durability And Adaptability:

Heavy-duty chassis structure with key components made from wear-resistant materials for harsh conditions; optional dust removal and noise reduction modules enhance environmental performance.

|

|

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

🟠1. Mobile Positioning: Utilizing a hydraulically driven tracked chassis, the equipment can autonomously move to designated workstations and stabilize in position.

🟠2. Material Feeding: Materials are conveyed into the vibrating screen's feed hopper via loading equipment (e.g., excavators, loaders) or conveyor belts from upstream units (e.g., mobile crushers). Alternatively, a dedicated feeder can be directly integrated.

🟠3. Core Screening: Vibration motors (or exciters) generate powerful vibrations, driving the screen box and mesh to oscillate at high frequencies. Material is thrown upward on the screen and separated into layers by gravity.

🟠4. Particle Size Classification: Material smaller than the screen mesh aperture (undersize material) passes through the screen and falls onto the lower screen layer or into a designated undersize hopper/conveyor belt; Material larger than the aperture (oversize material) moves along the screen surface to the front end for discharge.

🟠5. Product Output: Screened materials of different specifications are transported via side-mounted or rear-mounted discharge belt conveyors (typically foldable/telescopic) to designated stockpile areas or downstream equipment.

Model | Feeder | Vibrating Screen | Belt Conveyor | 1 Layer Discharge Belt | 2 Layer Discharge Belt | 3 Layer Discharge Belt | Transfer Belt | Underscreen Belt | Capacity |

YMS12 | YSF1520 | 3YK1247 | B800x9m | B500x5.5m | B500x6.5m | B500x6.5m | B500x2.5m | B800x6.5m | 60-150t/h |

YMS15T | YSF1830 | 2YK1548 | B1000x11m | B500x6.5m | B500x7.5m | — | — | B800x8.5m | 120-250t/h |

YMS15 | YSF1830 | 3YK1548 | B1000x11m | B500x6.5m | B500x7.5m | B500x7.5m | B500x2.5m | B800x8.5m | 120-250t/h |

YMS18T | YSF1840 | 2YK1860 | B1000x15m | B500x6.5m | B500x7.5m | — | — | B1000x10m | 150-350t/h |

YMS18 | YSF1840 | 3YK1860 | B1000x15m | B500x6.5m | B500x7.5m | B500x7.5m | B500x2.8m | B1000x10m | 150-350t/h |

YMS20T | YSF2040 | 2YK2060 | B1000x15m | B650x7.5m | B650x7.5m | — | — | B1000x10m | 200-400t/h |

YMS20 | YSF2040 | 3YK2060 | B1000x15m | B650x7.5m | B650x7.5m | B650x7.5m | B650x2.8m | B1200x10m |