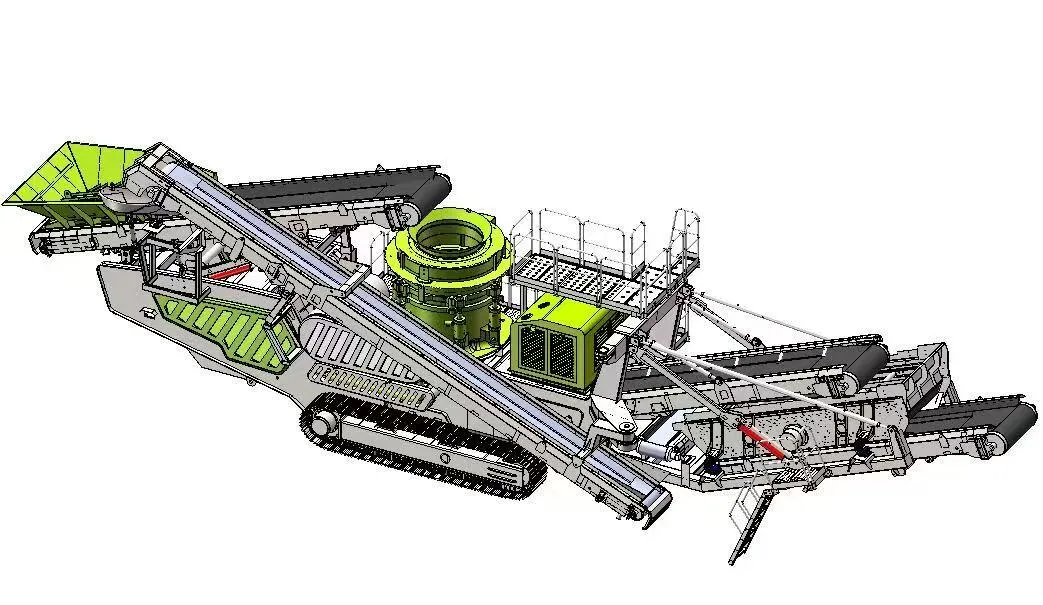

Hard rock crushing expert, primarily used for secondary and tertiary crushing operations in metal mines and construction aggregate processing, serving as the core equipment for fine crushing in mining. The tracked cone crushing plant, with its outstanding crushing performance and mobile convenience, is frequently employed in applications such as highway construction, railway ballast, and concrete aggregate production.

Crawler-mounted cone crushers are typically integrated with crawler-mounted jaw crushers and crawler-mounted vibrating screens to form complete aggregate crushing production lines.

|  |

🟠1. Hard Rock Crusher, High Output with Low Consumption:

The cone crusher, featuring a core laminar crushing principle, is specifically engineered for crushing highly abrasive hard rocks such as granite, basalt, and river pebbles. Its optimized crushing chamber and efficient drive system, combined with intelligent hydraulic discharge adjustment, ensures consistent particle size while achieving higher output per unit time. This significantly reduces energy consumption per ton of output, enhancing overall operational efficiency.

🟠2. Superior Particle Shape, Precise Gradation:

Layer crushing produces more cubical particles with minimal needle and flake content. The finished aggregate boasts excellent particle shape and controllable gradation, making it ideal raw material for high-end concrete, asphalt mixing, and manufactured sand production, substantially enhancing product value.

🟠3. Rapid Relocation, Energy Efficiency & Environmental Protection:

No disassembly or reassembly required upon project completion or site change. Deployment at new locations within hours substantially increases equipment utilization and significantly shortens project cycles. Dual-power system with intelligent diesel-electric switching achieves 25% fuel savings, while pure electric mode meets urban environmental requirements.

🟠4. Smart Integration, User-Friendly Operation:

The integrated unit combines feeding, crushing, screening (optional), and conveying functions. Equipped with an advanced electronic control system, it offers high automation, simplified operation and maintenance, effectively reducing labor dependency and operational costs.

|  |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

Device/Model | STP430RS | STH300RS | STH400RS | STH300RS(E) |

Feeding Department | ||||

Bin Volume(m³) | 5 | 6.5 | 6.5 | 6.5 |

Feeder Model | B1000 | B1200 | B1200 | B1200 |

Feeder Power(KW) | 11 | 15 | 15 | 22 |

Drive Mode | Motor Reducer | Motor Reducer | Motor Reducer | Motor Reducer |

Crusher | ||||

Device/Model | CS430 | HP300 | HP400 | HP300 |

Crusher Power(KW) | 132 | 220 | 315 | 220 |

Processing Capacity(t/h) | 150-200 | 110-440 | 135-630 | 110-440 |

Return Material Sieve | ||||

Device/Model | SX1536 | SX1545 | SX1545 | SX1545 |

Number Of Screen Layers | 1 | 1 | 1 | 1 |

Belt Conveyor | ||||

Main Belt Conveyor | B1200 | B1200 | B1200 | B1200 |

Side Belt Conveyor | B1200 | B1200 | B1200 | B1200 |

Material Return Belt Conveyor | B500 | B500 | B500 | B500 |

Drive Mode | Motor Reducer | Motor Reducer | Motor Reducer | Motor Reducer |

Machine Power(KW) | 184.4 | 293.4 | 388.4 | 293.4 |

Power System(KW) | Cummins 330 | Cummins 560 | Cummins 560 | Cummins 93 |